Your Draw a sketch of microstructures along the cooling lines images are ready. Draw a sketch of microstructures along the cooling lines are a topic that is being searched for and liked by netizens today. You can Get the Draw a sketch of microstructures along the cooling lines files here. Download all royalty-free images.

If you’re searching for draw a sketch of microstructures along the cooling lines images information related to the draw a sketch of microstructures along the cooling lines keyword, you have pay a visit to the ideal blog. Our site frequently provides you with hints for seeking the highest quality video and image content, please kindly surf and locate more informative video content and graphics that fit your interests.

Draw A Sketch Of Microstructures Along The Cooling Lines. 47 Simple Draw a sketch of microstructures along the cooling lines with Sketch Pencil Sep 09. Sheep Cattle Horses And Goats 18th Drawing. Amount of transformation is time independent characteristic amount of transformation completes in a very short time but function of temperature alone. Changing temperature andor pressure eg.

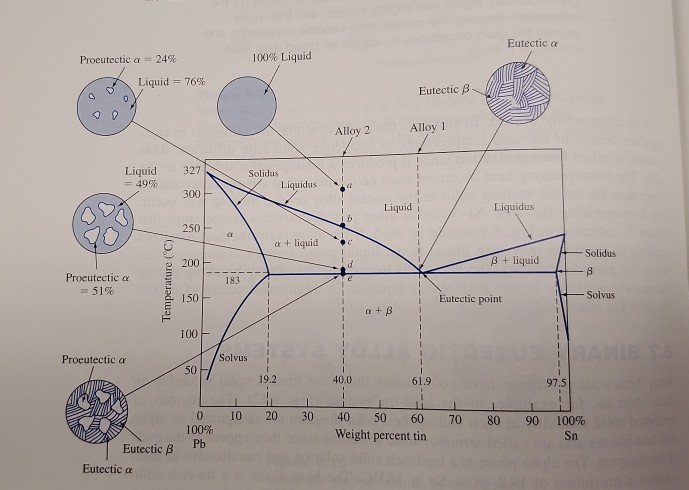

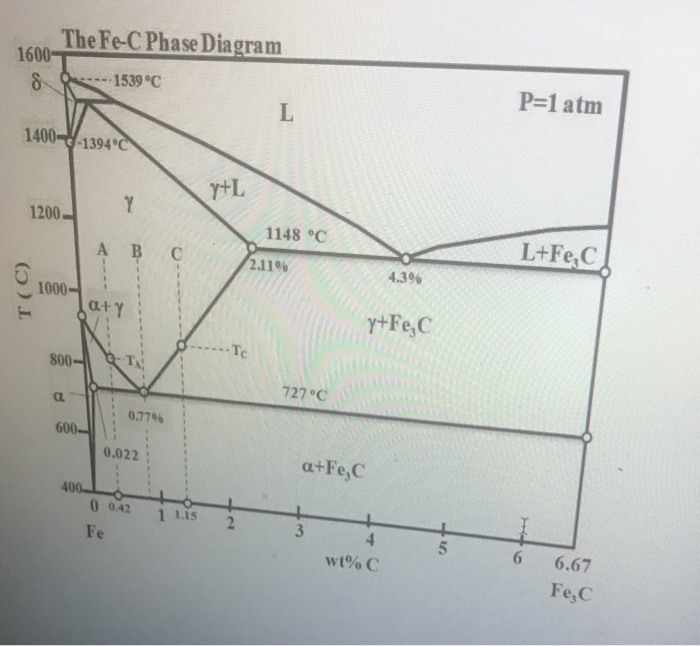

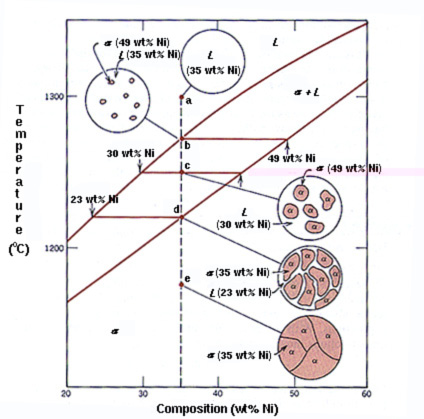

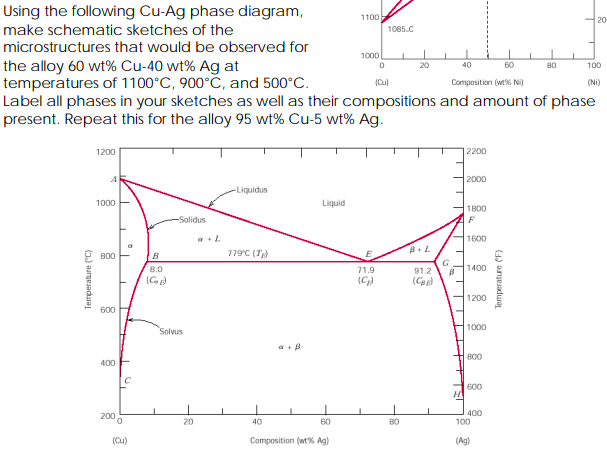

Mar 2 2018 - Explore Jeffrey Changs board Tattoo Horse followed by 239 people on Pinterest. The examples provided are. The intersection of the tie line with the solidus line meets the composition axis at 425 wt Ni 575 wt Cu which is the composition of the α solid-solution phase Cα. Draw the cooling curve as quench-hold-quench cycle in the T TT diagram that would lead to 50 Pearlite and 50 Martensite. An alloy in this state shows no tendency to change it is thermodynamically. Teach Yourself Phase Diagrams A6 HRS 03112009 and Phase Transformations DEFThe equilibrium constitution is the state of lowest Gibbs free energy G for a given composition temperature and pressure.

Jeaus Riding On White Horse Drawing Tattoo Sketch More from This Artist.

In order to study the influence of drawing velocity change on directional solidification microstructures acceleration and deceleration are designed respectively as shown in Fig. For the same slip system and direction of the applied tensile stress calculate the magnitude of the applied tensile stress necessary to initiate yielding if critical resolved shear stress known to be equal to 30MPa. Make a labelled sketch of each one and add an appropriate scale bar. A melt crystallising to a solid on cooling. The intersection of the tie line with the liquidus line meets the composition axis at 315 wt Ni 685 wt Cu which is the composition of the liquid phase C L. Best Sketch Art with.

Source: researchgate.net

Source: researchgate.net

Amount of transformation is time independent characteristic amount of transformation completes in a very short time but function of temperature alone. Consider the slow cooling of Fe-04 C steel under equilibrium conditions from say 1600C to room temperature. 47 Simple Draw a sketch of microstructures along the cooling lines with Sketch Pencil Sep 09. Amount of transformation is time independent characteristic amount of transformation completes in a very short time but function of temperature alone. The examples provided are.

Source: fractory.com

Source: fractory.com

The intersection of the tie line with the liquidus line meets the composition axis at 315 wt Ni 685 wt Cu which is the composition of the liquid phase C L. The transformation is athermal in nature. Most beginners struggle at sketching. Make a labelled sketch of each one and add an appropriate scale bar. A vertical line indicating the composition of the steel is drawn to discuss it.

Source: chegg.com

Source: chegg.com

Compute the resolved shear stress along 110 plane and -111 direction. E The steel alloy with 03 wt C exhibits only Pearlite. Mar 2 2018 - Explore Jeffrey Changs board Tattoo Horse followed by 239 people on Pinterest. Consider the slow cooling of Fe-04 C steel under equilibrium conditions from say 1600C to room temperature. Amount of transformation is time independent characteristic amount of transformation completes in a very short time but function of temperature alone.

Source: researchgate.net

Source: researchgate.net

There should be a horizontal line here that indicates that there is a monotectic reaction viz. The intersection of the tie line with the liquidus line meets the composition axis at 315 wt Ni 685 wt Cu which is the composition of the liquid phase C L. Make a labelled sketch of each one and add an appropriate scale bar. Changing temperature andor pressure eg. The examples provided are.

Source: chegg.com

Source: chegg.com

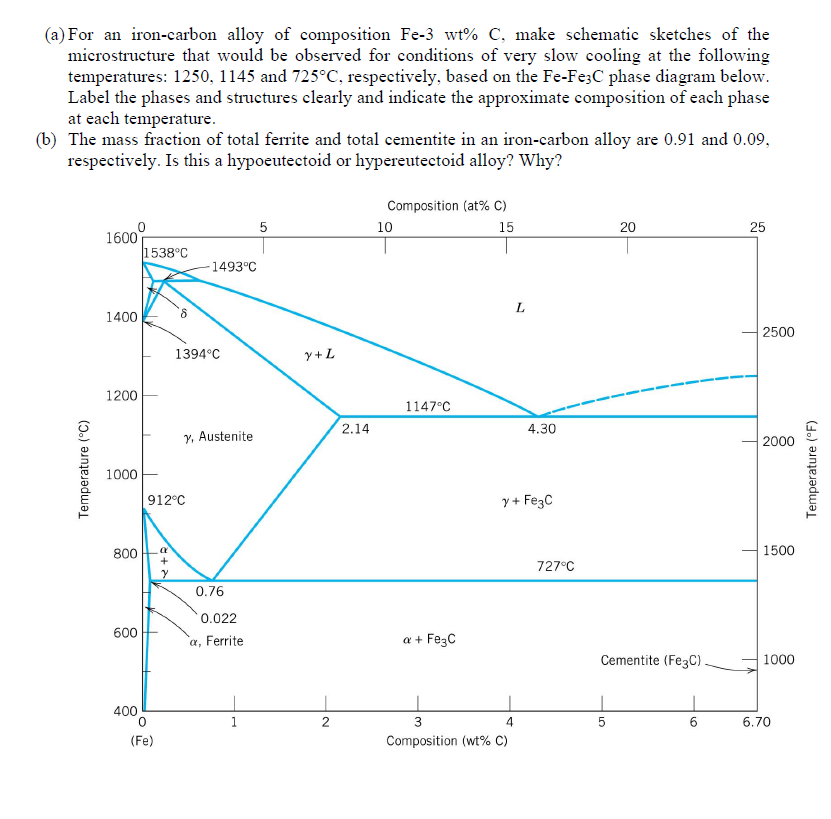

The examples provided are. The number of components are 2 XO and YO and the number of phases in equilibrium are 2 XO L XY2O3. 127 illustrates part of the Fe-Fe3C diagram along with the thermal cooling curves of some steels which are discussed below. The examples provided are. What to sketch to learn how to draw faster.

Source: chegg.com

Source: chegg.com

A melt crystallising to a solid on cooling. To begin a gestural. 47 Simple Draw a sketch of microstructures along the cooling lines with Sketch Pencil Sep 09. The intersection of the tie line with the liquidus line meets the composition axis at 315 wt Ni 685 wt Cu which is the composition of the liquid phase C L. Changing temperature andor pressure eg.

Source: chegg.com

Source: chegg.com

47 Simple Draw a sketch of microstructures along the cooling lines with Sketch Pencil Sep 09. The intersection of the tie line with the solidus line meets the composition axis at 425 wt Ni 575 wt Cu which is the composition of the α solid-solution phase Cα. The liquid can not have a composition range since this is an invariant reaction according to the condensed Gibbs phase rule P F C 1. Tensile stress 52MPa is applied along 010 direction. Draw the cooling curve as quench-hold-quench cycle in the T TT diagram that would lead to 100 Pearlite.

1The DS samples with different drawing velocity and nominal contents of Si were marked as A17 17Si acceleration D17 17Si deceleration A16 16Si acceleration D16 16Si deceleration. A vertical line indicating the composition of the steel is drawn to discuss it. To begin a gestural. Tensile stress 52MPa is applied along 010 direction. Consider the slow cooling of Fe-04 C steel under equilibrium conditions from say 1600C to room temperature.

Source: sv.rkriz.net

Source: sv.rkriz.net

Best Sketch Art with. Compute the resolved shear stress along 110 plane and -111 direction. 127 illustrates part of the Fe-Fe3C diagram along with the thermal cooling curves of some steels which are discussed below. The liquid can not have a composition range since this is an invariant reaction according to the condensed Gibbs phase rule P F C 1. What to sketch to learn how to draw faster.

Source: youtube.com

Source: youtube.com

47 Simple Draw a sketch of microstructures along the cooling lines with Sketch Pencil Sep 09. There should be a horizontal line here that indicates that there is a monotectic reaction viz. For the same slip system and direction of the applied tensile stress calculate the magnitude of the applied tensile stress necessary to initiate yielding if critical resolved shear stress known to be equal to 30MPa. The intersection of the tie line with the liquidus line meets the composition axis at 315 wt Ni 685 wt Cu which is the composition of the liquid phase C L. What To Sketch To Learn How To Draw Faster We have learned how to hold a pencil to write so its a natural urge to drawFor quick more free-form drawing one might try to use very large paper chalk or high number soft lead pencil and draw using the whole arm and even body in broad sweeping.

Source: researchgate.net

Source: researchgate.net

Draw the cooling curve as quench-hold-quench cycle in the T TT diagram that would lead to 50 Pearlite and 50 Martensite. On cooling of metastable austenite 1 martensite forms at about 230C. For the same slip system and direction of the applied tensile stress calculate the magnitude of the applied tensile stress necessary to initiate yielding if critical resolved shear stress known to be equal to 30MPa. The transformation is athermal in nature. The examples provided are.

Source: researchgate.net

Source: researchgate.net

Most beginners struggle at sketching. 21 How microstructures form. Sheep Cattle Horses And Goats 18th Drawing. Draw the cooling curve as quench-hold-quench cycle in the T TT diagram that would lead to 50 Pearlite and 50 Martensite. Mar 2 2018 - Explore Jeffrey Changs board Tattoo Horse followed by 239 people on Pinterest.

Source: sciencedirect.com

Source: sciencedirect.com

127 illustrates part of the Fe-Fe3C diagram along with the thermal cooling curves of some steels which are discussed below. To begin a gestural. Consider the slow cooling of Fe-04 C steel under equilibrium conditions from say 1600C to room temperature. Changing temperature andor pressure eg. The intersection of the tie line with the liquidus line meets the composition axis at 315 wt Ni 685 wt Cu which is the composition of the liquid phase C L.

Source: chegg.com

Source: chegg.com

The intersection of the tie line with the liquidus line meets the composition axis at 315 wt Ni 685 wt Cu which is the composition of the liquid phase C L. An alloy in this state shows no tendency to change it is thermodynamically. Most beginners struggle at sketching. Consider the slow cooling of Fe-04 C steel under equilibrium conditions from say 1600C to room temperature. The liquid can not have a composition range since this is an invariant reaction according to the condensed Gibbs phase rule P F C 1.

Source: researchgate.net

Source: researchgate.net

Consider the slow cooling of Fe-04 C steel under equilibrium conditions from say 1600C to room temperature. 127 illustrates part of the Fe-Fe3C diagram along with the thermal cooling curves of some steels which are discussed below. Microstructures can be created through deformation or processing of the material eg. Consider the slow cooling of Fe-04 C steel under equilibrium conditions from say 1600C to room temperature. 100 linesmm taking care to focus.

Source: chegg.com

Source: chegg.com

The liquid can not have a composition range since this is an invariant reaction according to the condensed Gibbs phase rule P F C 1. Consider the slow cooling of Fe-04 C steel under equilibrium conditions from say 1600C to room temperature. The number of components are 2 XO and YO and the number of phases in equilibrium are 2 XO L XY2O3. The intersection of the tie line with the solidus line meets the composition axis at 425 wt Ni 575 wt Cu which is the composition of the α solid-solution phase Cα. Mar 2 2018 - Explore Jeffrey Changs board Tattoo Horse followed by 239 people on Pinterest.

Source: researchgate.net

Source: researchgate.net

Best Sketch Art with. Microstructures can be created through deformation or processing of the material eg. Make a labelled sketch of each one and add an appropriate scale bar. E The steel alloy with 03 wt C exhibits only Pearlite. For the same slip system and direction of the applied tensile stress calculate the magnitude of the applied tensile stress necessary to initiate yielding if critical resolved shear stress known to be equal to 30MPa.

Source: researchgate.net

Source: researchgate.net

Best Sketch Art with. The transformation is athermal in nature. On cooling of metastable austenite 1 martensite forms at about 230C. Compute the resolved shear stress along 110 plane and -111 direction. Draw the cooling curve as quench-hold-quench cycle in the T TT diagram that would lead to 100 Pearlite.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title draw a sketch of microstructures along the cooling lines by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.